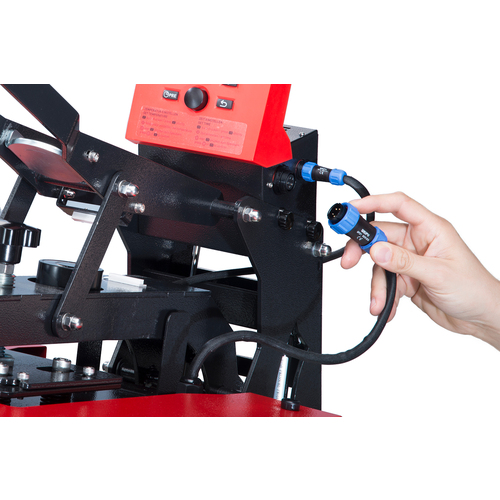

This latest development of the successful automatic knee-lever press Secabo TC7 MEMBRANE introduces a world novelty to the market, which opens up a variety of new options to users: The controller of the TC7 SMART MEMBRANE now comes equipped with a Bluetooth interface that allows for controlling the press via the free app Secabo Smart Transfer, while also providing access to a comprehensive function database. This allows users to: Simply enter the type of fabric and the transfer material and immediately retrieve the matching combinations of temperature, time and pressure. Additional features, such as the calculation of heat-up times and warning functions, make the app a valuable assistant for all common heat transfer methods. The new heat press Secabo TC7 SMART MEMBRANE offers a work surface of 40 x 50 cm, is easy to use and robust in ongoing operation. With regards to the base plate, the heat press is provided with a passive membrane. It creates new opportunities in the implementation of your Secabo heat press - especially when working with transfer objects with large differences in height and unevennesses. The membrane can easily be inflated using a small inflation bulb. The membrane's maximum compensation height may be configured thereby. The contact pressure is configured via a large hand wheel located at the upper side of the heat plate. When the heat press is closed, a manometer reliably displays the current contact pressure in grams per square centimeter. Further fine-tuning while pressing is possible via the inflation bulb and a release valve. The TC7 SMART MEMBRANE allows for taking accurate readings of the actual contact pressure, as well as reproducibly setting it. The modular design allows for quick and easy installation of replaceable base plates in various formats, a quick change system and a slide extension.

- World novelty for transfer presses: Bluetooth interface for Secabo Smart Transfer App with its own transfer database and numerous additional features

- Digital controller for temperature, time, prepressing, counting and many other features

- 100% new construction and new electronics including display and control concept

- Modular design, compact dimensions, lightweight packages

- Large differences in height can be compensated for in transfer objects

- The current contact pressure is always readable

- The same contact pressure is always reproducible adjustable

- No compressor required, passive diaphragm with fan ball and drain valve

| Dimensions open | 47cm x 93cm x 80cm |

| Dimensions closed | 47cm x 57cm x 80cm |

| working area | 40cm x 50cm |

| Size Diaphragm base plate | 47cm x 57cm |

| scope of delivery | Mechanical base, Heating plate, Base plate, Diaphragm base plate, Fastening set, Controller Box, C13 Power cable, Tools, Operating instructions |

| pressure setting | Height adjustment of the heating plate by means of handwheel, fine adjustment with blower ball and drain valve of the diaphragm |

| max. downforce | 250 g/cm² |

| max temperature | 225 °C |

| maximum time preset | 999 s |

| max. clam angle | 40 ° |

| power supply | AC voltage 230V / 50Hz - 60Hz, 2.0kW |

| environment | +5°C - +35°C / 30% - 70% humidity |

| weight without packaging | 39 kg |

| weight with package | 61,60 kg |

| Brand | Secabo |

YouTube Video

By loading the video, you accept YouTube's privacy policy.

YouTube Video

By loading the video, you accept YouTube's privacy policy.

YouTube Video

By loading the video, you accept YouTube's privacy policy.